28 Air Handlers—New Installation

Symptoms:

Within 6 months of the grand opening, complaints about lack of air flow, vibrating floors, and system trips were “flowing” in.

Examination and Diagnosis:

VIBRATION ANALYSIS pointed to worn/pitted bearings. Motors had 3 months to live.

Treatment:

Bearings proved to be pitted. They were bone-dry and discolored from heat, despite a PM schedule! We performed corrective action and CRITICAL SPEED ANALYSIS. We designed an optimized PM program, and management insisted we perform PREFUNCTIONAL TESTING on all future installs and PERIODIC MONITORING of all equipment. Performance is now optimal.

Return on Investment (ROI):

Avoided catastrophic failure of ¾ of the motors, saving $200k-$300k. Downtime would have severely impacted hotel revenue & client satisfaction. Future maintenance costs were reduced by improving operator performance.

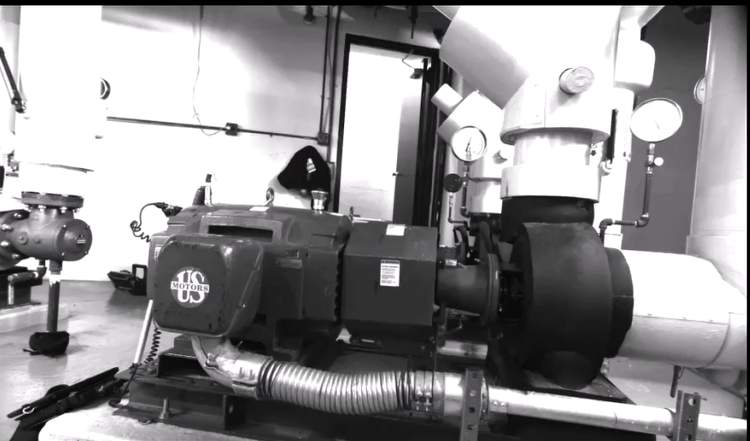

Motion Amplification detects and visualizes vibration caused by lack of VFD speed calibration

Symptoms:

Four catastrophic failures on a critical pump? That's four too many! Yet, that was the reality for a major client until they called in PRETECT and utilized Motion Amplification®.

Examination and Diagnosis:

PRETECT's Reliability and Quality Assurance team performed a thorough inspection, vibration analysis, and Motion Amplification using high-speed cameras.

Treatment:

The root cause? A simple yet critical oversight: the lack of VFD critical speed calibration for the pump and the incorrect sequence of operations from pump to pump.

Return on Investment (ROI):

Using Motion Amplification made it much EASIER and quicker to troubleshoot and visualize VFD induced vibration problems.