PRETECT provides expert vibration analysis, monitoring, and machinery health reporting services, designed to help optimize the performance and reliability of your machinery.

With over 35 years of experience, PRETECT delivers these services across a wide range of industries, offering in-depth insights into the health of your equipment.

Our Services Include:

> Periodic Vibration Monitoring

> Advanced Troubleshooting

> Remote Vibration Monitoring

Why Choose PRETECT for Vibration Analysis?

> Certified Technicians

> Comprehensive Reporting

> Tailored Solutions

Use Cases:

> Predictive Maintenance (PdM) | Reliability Centered Maintenance | Condition Monitoring

> Acceptance Testing | Commissioning | Alignment verifications

> Baseline new or rebuilt equipment | VFD Critical Speed Analysis | Warranty

Common Applications:

> Motors | Pumps | Blowers | Fans

> Chillers | Compressors | CRAC Units | HVAC

> Cooling Towers | Generators

Common Faults Detected:

> Bearing Defects |Imbalance | Mechanical Looseness

> Misalignment | Soft Foot | Bent Shafts

> Resonance | Gearbox defects | Worn Isolators

PRETECT offers infrared thermography inspection and reporting services for proactive equipment monitoring and maintenance.By using state-of-the-art infrared camera technology, we can detect potential issues before they lead to costly failures or safety risks.

Common Use Cases:

-Electrical Inspections

-Mechanical Inspections

-Predictive Maintenance

-Acceptance Testing

-Commissioning

-Post Repair Verification

Common Faults Detected:

-Overheating Components

-Loose Electrical Connections

-Mechanical Wear

-Insulation issues

-Misalignment

Let PRETECT perform your thermographic inspection and gain peace of mind knowing your equipment and facilities are in top condition.

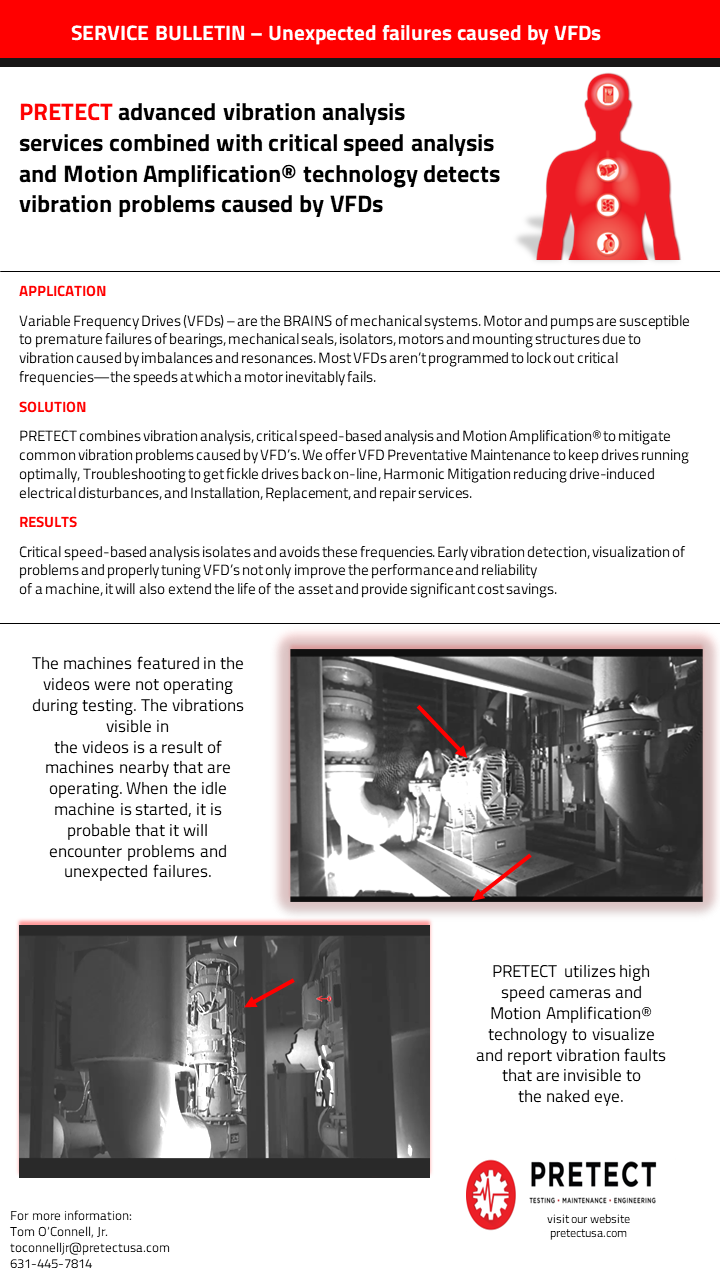

PRETECT offers Motion Amplification® (MA), a non-contact and video-based Vibration Analysis and Fault Visualization service that combines high speed cameras, patented vibration visualization technology, software processing algorithms, analysis and reporting.

The key benefit of MA is that Visualization shows you faults NOT evident to naked eye. The videos are amplified to visualize machinery faults and pinpoint root causes that might otherwise be difficult to detect using traditional sensor methods.

Click here to learn more and see case studies: Motion Amplification

|

Use Cases: > Acceptance Testing > Commissioning > Before/After Alignments > Predictive Maintenance > Vibration Troubleshooting > Warranty Claims |

|

Common Applications: > Motors, Fans and Pumps > Air Handling , CRAC Units > Chillers, Gearboxes, > Elevator Hoists > Engines, Generators > Bases, Piping, Structures |

|

Common Faults Detected: > Unbalance, misalignment > Loose or worn anchor bolts > Structural cracks / defects > VFD (lack of speed calibration) > Piping vibration > Natural frequencies |

PRETECT MA reporting includes vibration data, MP4 videos, detailed analysis and prioritized repair actions to solve vibration issues.

PRETECT utilizes cutting-edge laser alignment technology to correct one of the most common causes of vibration in rotating equipment.

Misalignment and Soft foot is a leading cause of premature wear in rotating equipment and components such as bearings, seals, and couplings from excessive strain.

By improving alignment and addressing soft foot conditions, we help extend the lifespan and reliability of your machinery.

Key Benefits:

-Reduce Vibration

-Decrease Component Wear

-Lower Power Consumption

-Extend Equipment Life

When you schedule alignment services with PRETECT, you can trust our experts to align your equipment to the highest industry standards, ensuring optimal performance and reliability.

Variable Frequency Drives (VFDs) - The Brain of Your Mechanical Systems

When VFDs are not properly configured, they can lead to premature failures in critical components. Vibration caused by imbalances and resonances in the system can cause undue wear on bearings, mechanical seals, isolators, motors, and mounting structures.

Most VFDs aren’t programmed to lock out critical frequencies—the speeds at which a motor inevitably fails. Critical Speed Analysis isolates and avoids these frequencies.

We offer VFD Preventative Maintenance to keep drives running optimally, Troubleshooting to get fickle drives back on-line, Harmonic Mitigation reducing drive-induced electrical disturbances, and Installation, Replacement, and Repair services.

PRETECT combines advanced vibration analysis, critical speed-based analysis, and Motion Amplification® to mitigate common vibration problems caused by VFDs.

Our VFD Services include:

> VFD Preventative Maintenance

> VFD Troubleshooting

> Harmonic Mitigation

> VFD Speed Calibrations

CASE STUDY - CLICK TO VIEW VIDEO

To enhance the performance and lifespan of your VFD systems, contact PRETECT today at Online Service Request Form